I spent the last couple weekends moving the boat and tools into the “Boat Barn.” I just started working towards installing the bulkheads and took some more notes and pictures.

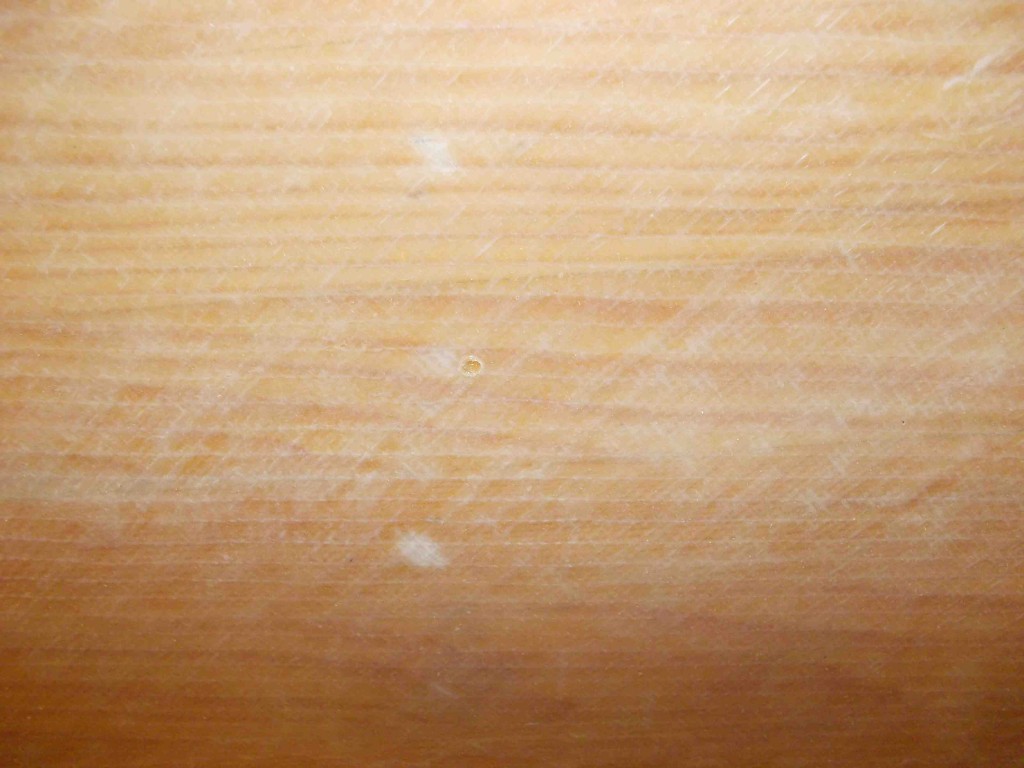

Here is a picture of why you want to fill all the staple holes. You can see an air bubble that made its way to the surface. These bubbles allow a direct path for the water to seep into the hull. Fixing them is not hard, but not having them to begin with is better.

Here is a better picture of how the biaxial glass lays down and the filling required to sand it smooth. I wonder if adding a very light woven cloth as the top layer would make fairing easier.

At this point I decided to sand all of the interior surfaces to 80 grit to simplify bonding the bulkheads. At first I thought I would only sand where needed, but decided to just prep the whole interior surface.

Bulkheads cut and in place

Ooops! this what happens when you read a 3 when it is supposed to be an 8. Bulkhead #4 off by 50mm in height. Notice the low shear corner…