I am getting ready to move the boat to a nice heated garage over the winter. I decided that I would attach the keels after decking the boat to make it easier to work on the interior. That has the additional benefit of making the cradle much easier to built.

The bottoms are 2×12 – 4ft

The sides 2×8 – 8ft

4 metal corner brackets hold it together.

I used frames 3 1/2 and 7 + 15mm offset to get the profile for the bunkers.

I spent the last couple weekends moving the boat and tools into the “Boat Barn.” I just started working towards installing the bulkheads and took some more notes and pictures.

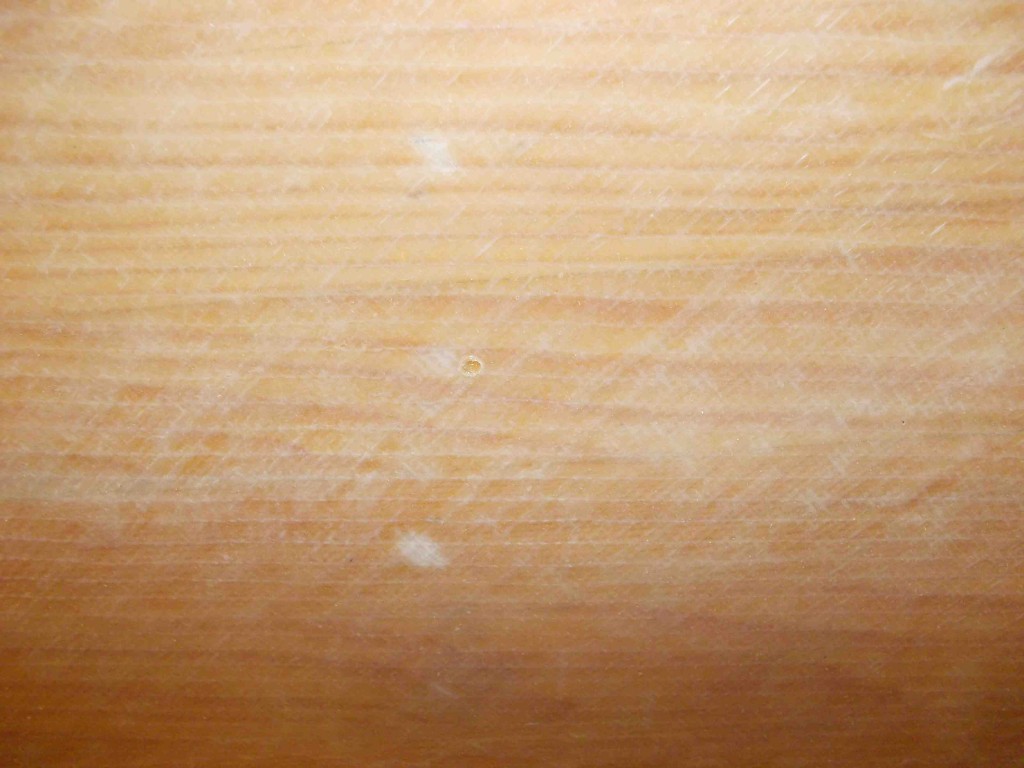

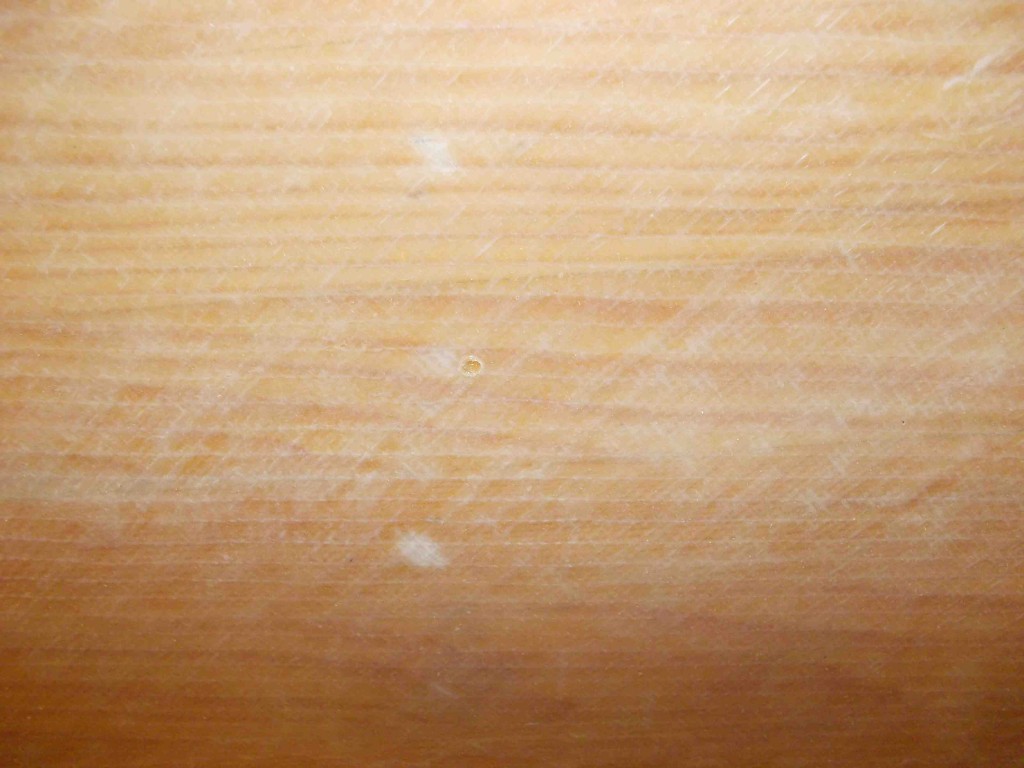

Here is a picture of why you want to fill all the staple holes. You can see an air bubble that made its way to the surface. These bubbles allow a direct path for the water to seep into the hull. Fixing them is not hard, but not having them to begin with is better.

Here is a better picture of how the biaxial glass lays down and the filling required to sand it smooth. I wonder if adding a very light woven cloth as the top layer would make fairing easier.

At this point I decided to sand all of the interior surfaces to 80 grit to simplify bonding the bulkheads. At first I thought I would only sand where needed, but decided to just prep the whole interior surface.

Bulkheads cut and in place

Ooops! this what happens when you read a 3 when it is supposed to be an 8. Bulkhead #4 off by 50mm in height. Notice the low shear corner…

Building a Shadow 24ft Woods Catamaran